Experimental and analytical facilities

Our workgroup has access to a number of experimental and analytical techniques, which are subdivided into four laboratory spaces: High-Pressure, High-Temperature, Chemical and Sample Preparation Facilities. To find out more about our Facilities please look at the detailed descriptions below.

High-pressure laboratory

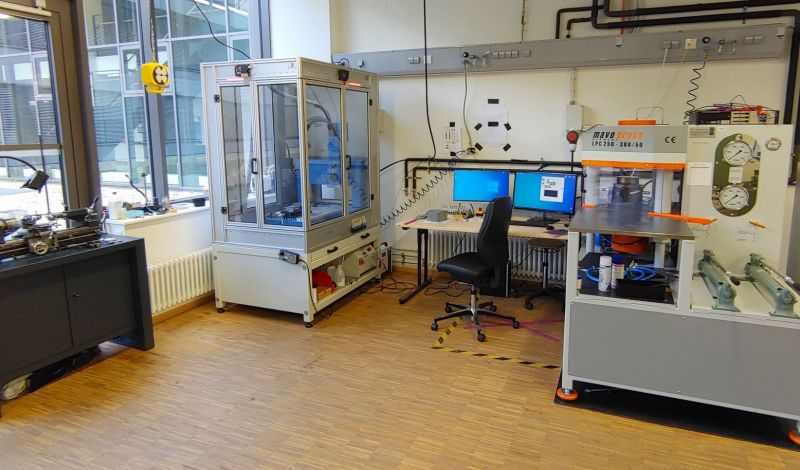

Our laboratory has two end-load piston-cylinder presses of different sizes. The high pressures between two rams are generated by specially designed high pressure cells. Pressures of up to 50 kbar (~ 5 GPa) and temperatures of up to 1700 °C can be achieved.

All presses are equipped with automatic pressure and temperature regulators, so that long test times are guaranteed under constant conditions without manual intervention. One of the presses also has the option of showing the piston displacement, which means that compressibility measurements can be carried out at high pressures. Up to 200 mg of sample material can be used, at higher pressures smaller amounts of around 10 mg.

The 630 ton Walker-type Multianvil press is used to generate pressures of up to 180 kbar (18 GPa) and temperatures up to 2000 °C). Solid pressure media equipped with a range of resistive heaters are used as sample containers. Both the pressure generation and the decompression take place in this device under computer control. The sample volume is even smaller than in the piston cylinder press - the rule of thumb says that the sample volume becomes smaller at higher pressure.

The hydrothermal laboratory consists of around 9 autoclaves, which are heated externally in tubular folding ovens. The pressure is generated via thin capillaries in which water is compressed to pressures of up to 4 kbar (0.4 GPa). Temperatures of up to 800 °C are reached within the folding ovens.

Advantages of this system compared to ram-cylinder presses are the large sample volumes one can do experiments on, and the fact that experiments can be run under stable conditions for weeks to months. The very precise pressure determination during the experiment should also be emphasized.

Room-Nr.: IB 03/150

Phone-Nr.: +49 (0) 234 32 19327

Contact: Christopher Beyer

High-Temperature Laboratory

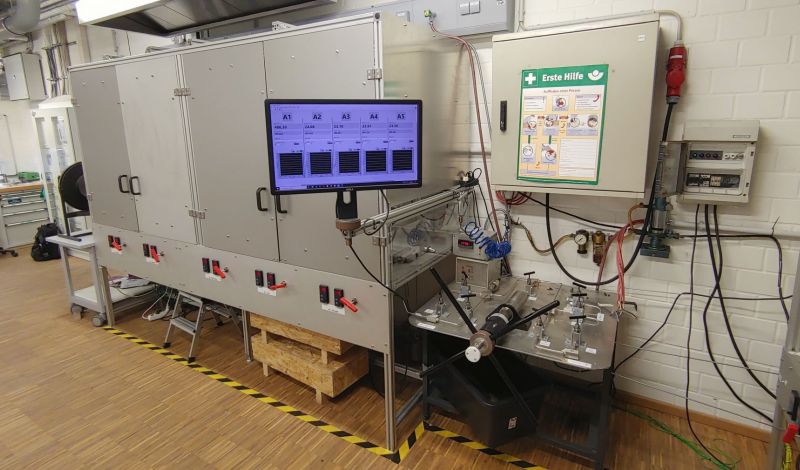

Our high-temperature laboratory facilities contain four Carbolite-Gero gas mixing furnaces, each equipped with CO and CO2 mass flow controllers and automatic temperature control. The gas mixing systems and temperature heating and cooling ramps are monitored and controlled via computer both on- and off-site. The use of different gas mixtures allows us to recreate the redox conditions prevalent in the interior of planetary bodies in the solar system. This allows us to study disparate processes like trace element behaviour during melting of planetary interiors as well as stable isotope fractionation behaviour (kinetic and equilibrium).

Evaporation experiments with solids and liquids can be carried out in this oven at very high temperatures. For example, the vapor phases that coexist with molten igneous fluids or minerals such as olivine can be studied along with the isotope fractionation effects that occur during such evaporation / condensation reactions. It has been shown that such evaporation also affects the nature of surfaces and defects in crystals, and these are aspects that are being investigated in our research group. This furnace is located in the RUBION buildings on the university campus.

Room-Nr.: IA 02/135

Phone Nr.: +49 (0) 234 32 24124

Contact: Christopher Beyer

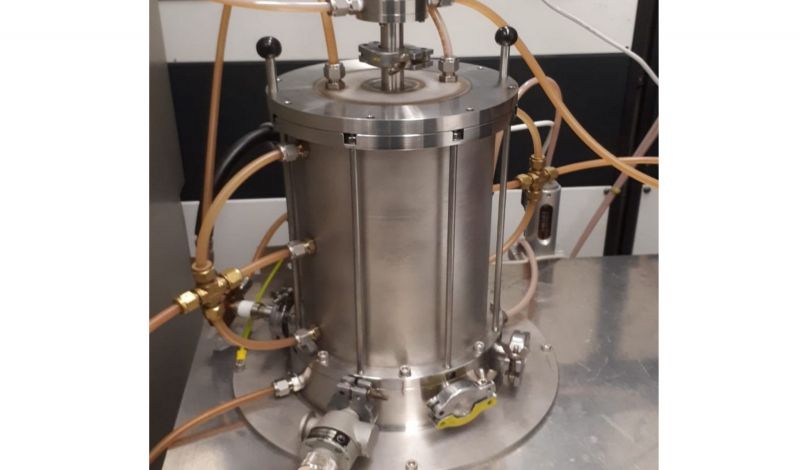

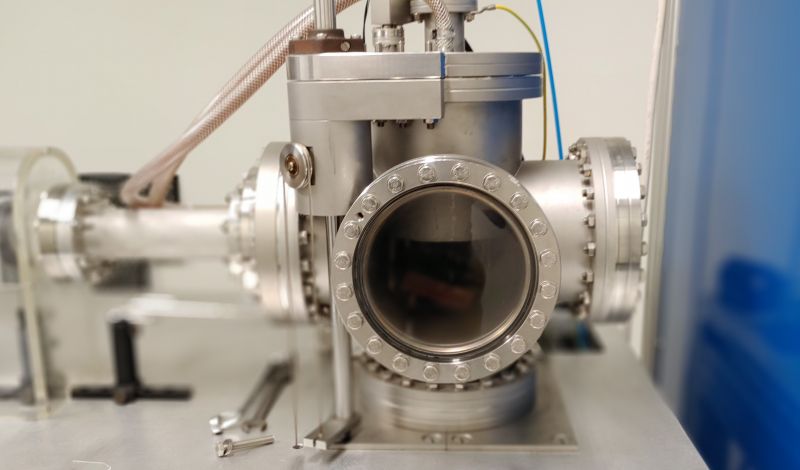

Pulsed laser deposition (PLD) laboratory

Producing thin films of complex refractory materials such as silicates and oxides was not possible in the past. Advances in the techniques of pulsed Laser ablation using an excimer laser have now made it possible to produce such thin films, which enable a variety of diffusion and other kinetic studies to be carried out. A laboratory for the production of such thin films is in place at the Institute of Geology, Mineralogy and Geophysics of the Ruhr-University at Bochum. It is the only one of its kind in the world that is dedicated to the production of thin films of mineralogical interest.

The equipment, built to suit our special needs, consists of an excimer laser capable of operating at three wavelengths (ArF - 193nm, KrF - 248nm and XeF 351 nm). This laser is powerful enough (pulse energies of 650 to 1200 mJ, maximum wattage of up to 50 and a frequency of 50 Hz) to convert refractory minerals (targets) stoichiometrically to a plasma. The plasma then deposits the material on the surface of a second solid object (substrate), which is typically the polished/cleaved surface of a mineral or rock. The high energy ensures tight bonding between the deposited thin film and the substrate, thereby producing excellent starting materials for diffusion and other kinetic or mechanical testing studies while the substrate is tempered.

Among the many advantages of this method are the speed and versatility with which a wide range of chemistry can be handled. We have so far produced, for example, thin films of olivines, garnets, pyroxenes, feldspars, perovskites and various oxides of complex chemistry, similar to those found in nature. We have also produced films of water bearing materials (e.g. micas, hydrous glasses). The deposited area is usually about 4x4 mm.

Further information in:

Dohmen, R., Becker, H.-W., Meißner, E., Etzel, T., and Chakraborty, S. (2002) Production of silicate thin films using pulsed laser deposition (PLD) and applications to studies in mineral kinetics, Eur. J. Mineral., vol. 14, pp. 1155-1168.

Room-No.: IB 02 80/164

Phone: +49 (0) 234 32 24394

Contact: Ralf Dohmen

Chemical Laboratories

The chemistry lab is able to analyze quantitatively the bulk chemical compositions of any inorganic solid material; e.g. rocks, ores, soils, cements, glasses, metals and alloys, technical products. Special requirements for the samples are given below. Only the inorganic part of fluids can be detected. Please note: All methods are destructive to the sample!

Atomic absorption spectroscopy (AAS) - VARIAN AA 300

Elements that can be analyzed: all elements with Z > 3 (lithium) requirements: the sample must be soluble in an inorganic solvent, the mass must exceed 1 mg (depends on the number of elements to be analyzed). Coulometric analyses of Carbon, Carbon dioxide, Sulfur, and H2O (in minerals as hydroxyl groups or as H2O, moisture) requirements: mass should exceed 10 mg/analysis (depends on the content).

Potentiometric determination of fluorine and Fe2+: Requirements: mass should exceed 50 mg/analysis (depends on the content) Determination of loss on ignition (l.o.i.).

Terms of use for the chemical laboratory (pdf)

Room-No.: IA 01 95/153

Phone: +49 (0) 234 32 24391

Contact: Thomas Fockenberg

X-Ray Fluorescence Spectroscopy (XRF) . Philips PW 2404

Elements that can be detected: all elements with Z > 9 (fluorine) except the noblel gases. Requirements: the mass of the sample should exceed approximately 1 g.

Room-No.: IB 02/91

Phone: +49 (0) 234 32 19703

Contact: Thomas Fockenberg

Sample Preparation and material synthesis

Our workgroup is well equipped to synthetize glasses and sinter sample powders in preparation for experimental work. To this end we have two Nabertherm muffle furnaces, which can reach up to 1700 ºC, with the ability of using an inert gas to prevent an oxidizing atmosphere during material synthesis.

We also have the capability of preparing gaskets, furnaces, and ceramic parts for high-pressure experiments via the use of a MillStep CNC precision milling machine, and a Procon precision lathe.

After the experiments are ready, we have the equipment to section (wire diamond saw), cut (diamond disk saw) and polish (Bühler polishing plate) experimental samples for further analysis.